Glass substrates: Future solutions for semiconductor packaging

Glass substrate is the future of semiconductor packaging light, now the rapid development of electronic technology, semiconductor components are more and more integrated, the size is getting smaller, which makes the need for high-performance materials more urgent. At this time, the glass substrate, with its unique nature, slowly become the semiconductor packaging industry. What are the characteristics of the glass substrate? The benefit? And its use in semiconductor packaging?

What is glass substrate?

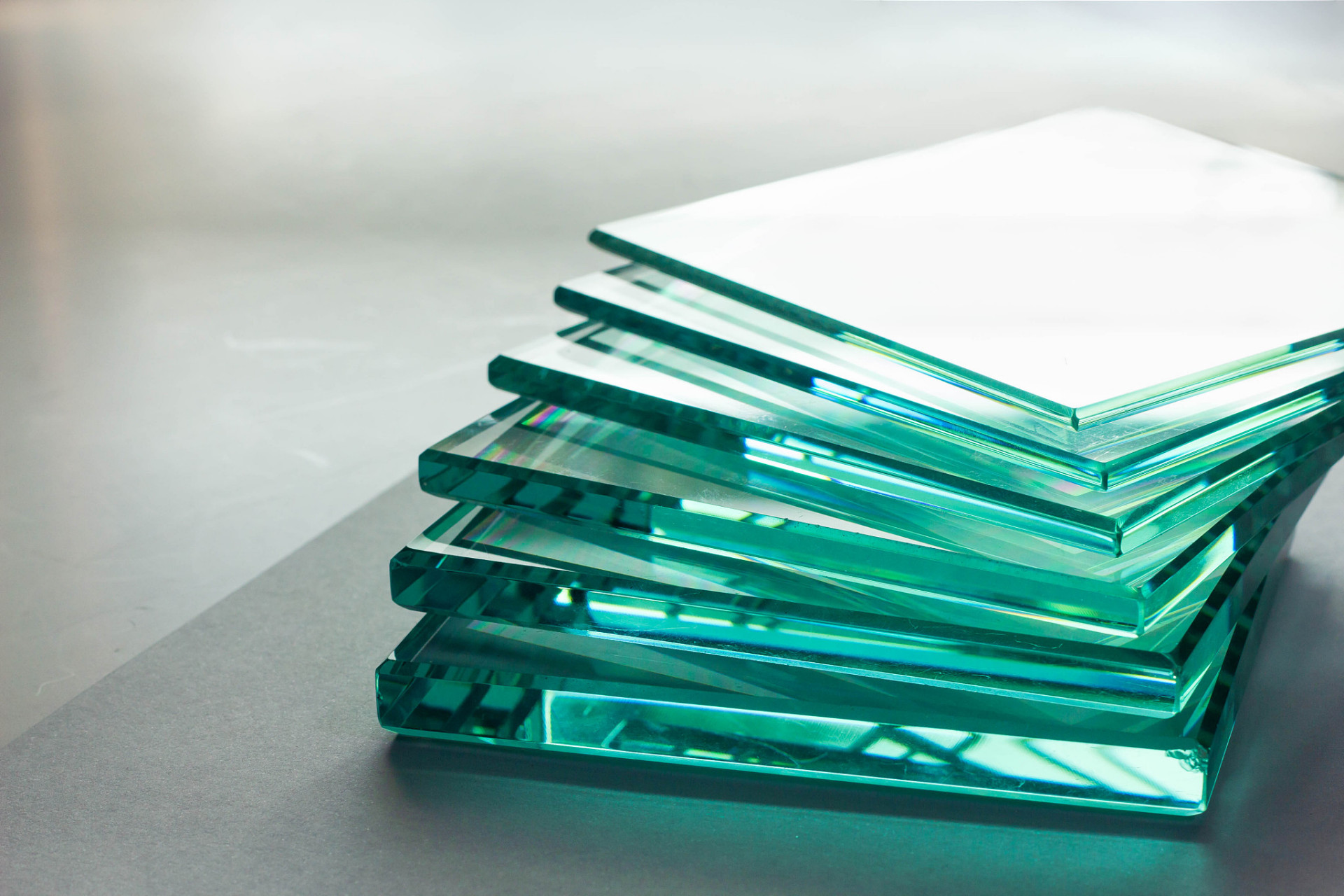

The glass substrate is a silica-based material made in a special way, which is generally made of high purity silicate glass or aluminosilicate glass with low diffusion coefficient. This material is made by melting and forming at high temperature, and has good optical properties, chemical stability, and mechanical strength. It is used in liquid crystal displays, touch screens, and semiconductor device packaging.

Glass substrate characteristics?

First, the thermal stability is particularly good, can withstand high temperature processing, and the thermal expansion coefficient is very close to silicon, so that when welding and packaging, the thermal stress can be controlled well, and the risk of hot cracks is reduced. In addition, it has excellent performance in charging and insulation, and the insulation performance is very good, which will not let the circuit leak or short circuit, and the reliability and safety of the device are guaranteed. And the glass surface is easy to clean, can make the package clean inside, not easy electrochemical corrosion. What's more, it's optically transparent, which is much better than traditional plastic substrates. This is particularly important in some optoelectronic applications, such as the packaging of optical sensors and lasers. Finally, the glass substrate can also be designed, the thickness and size of the manufacturing can be precisely controlled, and a variety of miniaturization design needs can be met. The cutting and etching process of glass can also complete complex structures, laying a good foundation for innovative semiconductor packaging methods.

What are the benefits of glass substrate?

First, the integration is higher, and now the electronic equipment is smaller, the integration is higher, and the high-density interconnection characteristics of the glass substrate make it a good choice to achieve IC packaging. Through miniaturization design, the circuit layout can be more dense, and the degree of functional integration will go up.

The second is to reduce costs, although the equipment and process for the production of glass substrate is very complex at the beginning, but it is durable, long-term stability is good, and the overall cost of finished products can be reduced by a lot in mass production. It takes longer and requires less maintenance, which saves money.

Finally, the environmental adaptability is good, and the glass material has strong chemical corrosion resistance and can work in harsh environments. Aerospace, medical equipment, these places with high environmental requirements can be used. Fourth, the thermal management ability is strong, the electronic components will heat up when they work, the glass substrate has good thermal conductivity, can help effectively heat dissipation, so that the device runs at a stable temperature, and the time is longer.

How to use glass substrate in semiconductor packaging?

In high-density interconnect packages, electronic products now have higher and higher circuit density requirements, and traditional packaging methods are a bit of a failure. When glass substrates are used, the performance of high density interconnect (HDI) packages can be greatly improved, because it has good electrical insulation and thermal stability, and can integrate more functions. In the sensor package, as soon as the Internet of Things devices become popular, the demand for sensors will increase. The glass substrate can give the sensor good protection, packaging can also ensure the sensitivity and accuracy of the sensor, especially in the field of environmental monitoring and biosensing. In RFID and wireless communications, the embedded design of the glass substrate can make the device smaller, and the signal transmission and processing power can be more powerful. In display technology, glass substrates are used in both liquid crystal display (LCD) and organic light-emitting diode (OLED) displays. In these places, the glass substrate can not only support, but also maintain good optical properties, so that the display effect is clear and bright.

Market prospects?

The global demand for high-performance electronic products is increasing, and the future of glass substrates in the semiconductor packaging market is great. It is estimated that in the next few years, with the rapid development of smartphones, wearable devices and Internet of Things products, the market share of glass substrates will be increasing. And the technology continues to improve, the glass substrate manufacturing process is becoming more and more mature, and the production cost is slowly coming down, which will make it used in more places. Many R & D teams and enterprises are actively studying the possibility of combining glass substrates with other new materials to create more diverse semiconductor solutions and increase future scientific and technological innovation.

In this way, with a comprehensive understanding of the characteristics, benefits and application scenarios of the glass substrate, we can see its importance in the semiconductor packaging industry. As the market changes, the glass substrate will continue to play its super performance and application potential, leading the semiconductor packaging to a better direction.

관심을 가질만한 제품

|

CCR0512FPXXXZ01A | AC/DC CONVERTER 12V 500W | 6264 More on Order |

|

EP3000AC48INZ | AC/DC CONVERTER 52V 3000W | 5688 More on Order |

|

AVX012A0X3-SRZ | DC DC CONVERTER | 4212 More on Order |

|

TJX120A0X3PZ | DC DC CONVERTER | 7344 More on Order |

|

AXA010A0A93-SRZ | DC DC CONVERTER 5V 50W | 5490 More on Order |

|

JNCW450R41-18Z | DC DC CONVERTER 32V 450W | 7704 More on Order |

|

QW010A0A1Z | DC DC CONVERTER 5V 50W | 7254 More on Order |

|

QRW040A0Y41 | DC DC CONVERTER 1.8V 72W | 2376 More on Order |

|

SC001A2B91Z | DC DC CONVERTER 12V 15W | 2196 More on Order |

|

AXH010A0X3Z | DC DC CONVERTER 0.8-3.6V 36W | 3258 More on Order |

|

QRW025A0F4 | DC DC CONVERTER 3.3V 83W | 4266 More on Order |

|

ME005B | DC DC CONVERTER 12V 5W | 4428 More on Order |

|

MC010A1 | DC DC CONVERTER 5V 10W | 7218 More on Order |

|

JW050C1 | DC DC CONVERTER 15V 50W | 7974 More on Order |

|

CC025ABK-M | DC DC CONVERTER 5V +/-12V 25W | 5634 More on Order |

|

ATS025A0X3 | DC DC CONVERTER 0.8-5.5V 137W | 6138 More on Order |

|

ATA010A0X43 | DC DC CONVERTER 0.8-5.5V 55W | 6426 More on Order |

|

QBDE067A0B641-PHZ | DC DC CONVERTER 12V 804W | 5382 More on Order |

|

JRCW016A0R41-18TZ | DC DC CONVERTER 28V 448W | 8910 More on Order |

|

ESTW010A0B641Z | DC DC CONVERTER 12V | 2574 More on Order |

|

EHHD020A0F641Z | DC DC CONVERTER 3.3V 66W | 6084 More on Order |

|

PKX020A0X43-SRZ | DC DC CONVERTER 0.6-3.63V | 6138 More on Order |

|

JRCW450R41Z | DC DC CONVERTER 32V 450W | 7596 More on Order |

|

ABXS001A4X41-SRZ | DC DC CONVERTER 32-54V 65W | 17724 More on Order |