How can infrared sensors improve AGV efficiency

Automated Guided Vehicle (AGV) is an important part of modern warehousing and production line, and its efficiency directly affects the operational efficiency of the whole logistics and production system. Compared with traditional logistics methods, AGVs can achieve unmanned operation, automatic driving, and even autonomous navigation in complex environments, greatly improving transportation efficiency and accuracy. In the process of AGV navigation, obstacle avoidance and positioning, infrared sensor, as a key sensing device, plays an indispensable role.

First, the working principle of infrared sensor

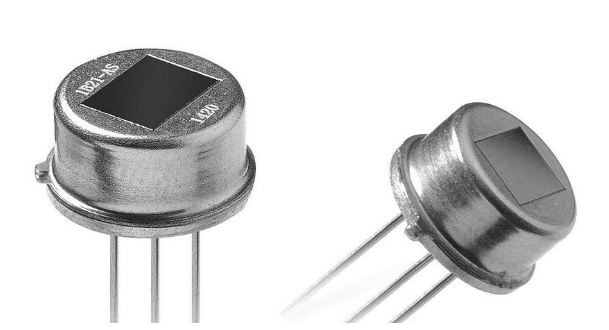

Infrared sensors mainly rely on transmitting and receiving infrared light waves to detect the presence and distance of objects. The basic principle is in the near infrared band, by emitting infrared light and detecting its reflected signal, using the intensity and time difference of the reflected light to calculate the distance and orientation of the target object. The infrared sensor has the characteristics of rapid response and high sensitivity, and can work effectively under various environmental conditions.

In AGV system, infrared sensors are widely used in obstacle detection, path tracking, edge detection and environmental monitoring. Its application scenarios include corners of warehouses, narrow passages and other complex structural areas to ensure that AGVs avoid collisions and accurately position during driving.

Second, the application of infrared sensor in AGV navigation

Navigation is one of the core functions of an AGV. Traditional navigation methods often rely on magnetic strips or lasers, and the CJ78L12 infrared sensor can provide a more flexible solution. With multiple infrared sensors installed on the AGV, the system is able to monitor the surrounding environment in real time and identify obstacles and driving routes. This multi-sensor fusion technology can improve the adaptive ability of AGVs to ensure high efficiency in dynamic environments.

For complex warehouse layouts, the flexibility of infrared sensors provides AGVs with better path planning capabilities. AGV can not only detect possible obstacles ahead through infrared sensors, but also quickly adjust the driving path on this basis to avoid collisions and ensure the continuity and efficiency of the transportation process.

Third, the importance of infrared sensors in obstacle detection

In the logistics process, the existence of obstacles will directly affect the operation efficiency of AGV. The infrared sensor can effectively identify the obstacles ahead and react in a very short time to stop the movement or go around. The rapid response of this process can effectively reduce the downtime caused by accidental collisions and reduce the cost of equipment maintenance.

Different from traditional ultrasonic sensors, infrared sensors have higher accuracy and reliability in detection, especially in low-light environments. The introduction of infrared sensors enables AGVs to maintain efficient operation even in complex working environments, saving a lot of human resources and time costs.

Fourth, the adaptability and intelligent characteristics of the infrared sensor

With the rapid development of artificial intelligence technology, the basic functions of infrared sensors have been further enhanced. Through multi-sensor fusion and data processing, infrared sensors can not only provide real-time environmental monitoring, but also generate more efficient driving strategies through learning and adaptation. For example, an AGV can optimize its travel path by learning its historical trajectory, reducing energy consumption and operating time.

In terms of data monitoring, infrared sensors can collect operational data in real time and optimize operational strategies through data analysis, thereby improving overall efficiency. Combined with cloud computing and Internet of Things (IoT) technologies, AGV systems can even interact with other logistics facilities in real time, forming a highly coordinated automated logistics system. Such an intelligent system can greatly improve work efficiency and resource utilization.

Fifth, the cost benefits of infrared sensors

The application of infrared sensor in AGV system brings direct benefits not only in efficiency improvement, but also in cost control. Through accurate obstacle detection and path planning, AGVs can reduce crashes and errors during transportation, reducing equipment wear and maintenance costs. At the same time, the AGV's adaptive driving strategy means that when changing the working environment, the system's ability to adapt to the environment is also enhanced, reducing the cost of retraining and retrofitting.

In addition, infrared sensors have low maintenance requirements and a long service life, helping to reduce operating costs in long-term use. Compared with other sensors, infrared sensors are more cost-effective, providing enterprises with greater advantages in the fierce market competition.

In summary, the application of infrared sensors in AGV systems reflects the combination of modern technology and production efficiency. By improving AGV navigation capabilities, optimizing obstacle detection, improving system intelligence and reducing operating costs, infrared sensors provide important technical support for improving the overall work efficiency of AGVs, and show their wide application prospects in the field of logistics and automation in the future.

관심을 가질만한 제품

|

TPCM-2.4-5 | CMC 2.41MH 5A 2LN TH | 6894 More on Order |

|

62051-P2S02 | XFRMR TOROIDAL 15VA CHAS MOUNT | 3312 More on Order |

|

62045-P2S02 | XFRMR TOROIDAL 10VA CHAS MOUNT | 2430 More on Order |

|

62044-P2S02 | XFRMR TOROIDAL 10VA CHAS MOUNT | 6048 More on Order |

|

62025-P2S02 | XFRMR TOROIDAL 5VA CHAS MOUNT | 3924 More on Order |

|

62021-P2S02 | XFRMR TOROIDAL 5VA CHAS MOUNT | 5058 More on Order |

|

62012-P2S02 | XFRMR TOROIDAL 3.2VA CHAS MOUNT | 3204 More on Order |

|

62005-P2S02 | XFRMR TOROIDAL 1.6VA CHAS MOUNT | 7668 More on Order |

|

62075-P2S02 | XFRMR TOROIDAL 35VA CHAS MOUNT | 7308 More on Order |

|

70074K | XFRMR TOROIDAL 35VA THRU HOLE | 6840 More on Order |

|

70072K | XFRMR TOROIDAL 35VA THRU HOLE | 5634 More on Order |

|

70043K | XFRMR TOROIDAL 10VA THRU HOLE | 5562 More on Order |

|

70031K | XFRMR TOROIDAL 7VA THRU HOLE | 8658 More on Order |

|

70024K | XFRMR TOROIDAL 5VA THRU HOLE | 8748 More on Order |

|

70014K | XFRMR TOROIDAL 3.2VA THRU HOLE | 5562 More on Order |

|

70013K | XFRMR TOROIDAL 3.2VA THRU HOLE | 4392 More on Order |

|

70011K | XFRMR TOROIDAL 3.2VA THRU HOLE | 7560 More on Order |

|

70002K | XFRMR TOROIDAL 1.6VA THRU HOLE | 5040 More on Order |

|

62024-P2S02 | XFRMR TOROIDAL 5VA CHAS MOUNT | 4824 More on Order |

|

62060-P2S02 | XFRMR TOROIDAL 25VA CHAS MOUNT | 23778 More on Order |

|

70034K | XFRMR TOROIDAL 7VA THRU HOLE | 8088 More on Order |

|

70005K | XFRMR TOROIDAL 1.6VA THRU HOLE | 7218 More on Order |

|

AC1015 | CURR SENSE XFMR 15A T/H | 5166 More on Order |

|

AC1025 | TRANSFORMER CURRENT 25.0 AMP | 4230 More on Order |